-

English

English -

Español

Español -

Português

Português -

русский

русский -

Français

Français -

日本語

日本語 -

Deutsch

Deutsch -

tiếng Việt

tiếng Việt -

Italiano

Italiano -

Nederlands

Nederlands -

ภาษาไทย

ภาษาไทย -

Polski

Polski -

한국어

한국어 -

Svenska

Svenska -

magyar

magyar -

Malay

Malay -

বাংলা ভাষার

বাংলা ভাষার -

Dansk

Dansk -

Suomi

Suomi -

हिन्दी

हिन्दी -

Pilipino

Pilipino -

Türkçe

Türkçe -

Gaeilge

Gaeilge -

العربية

العربية -

Indonesia

Indonesia -

Norsk

Norsk -

تمل

تمل -

český

český -

ελληνικά

ελληνικά -

український

український -

Javanese

Javanese -

فارسی

فارسی -

தமிழ்

தமிழ் -

తెలుగు

తెలుగు -

नेपाली

नेपाली -

Burmese

Burmese -

български

български -

ລາວ

ລາວ -

Latine

Latine -

Қазақша

Қазақша -

Euskal

Euskal -

Azərbaycan

Azərbaycan -

Slovenský jazyk

Slovenský jazyk -

Македонски

Македонски -

Lietuvos

Lietuvos -

Eesti Keel

Eesti Keel -

Română

Română -

Slovenski

Slovenski -

मराठी

मराठी -

Srpski језик

Srpski језик

- Home

- About Auwell

- Products

- Sheet Metal Fabrication

- Stamping

- Deep Drawing

- Casting

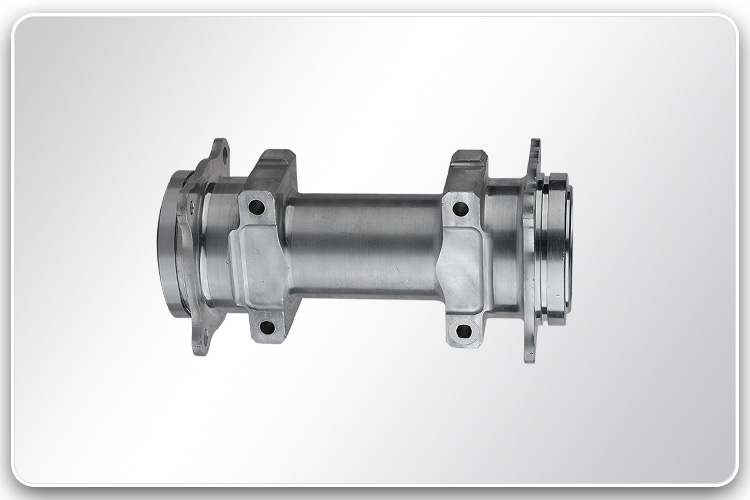

- High Pressure Die Casting

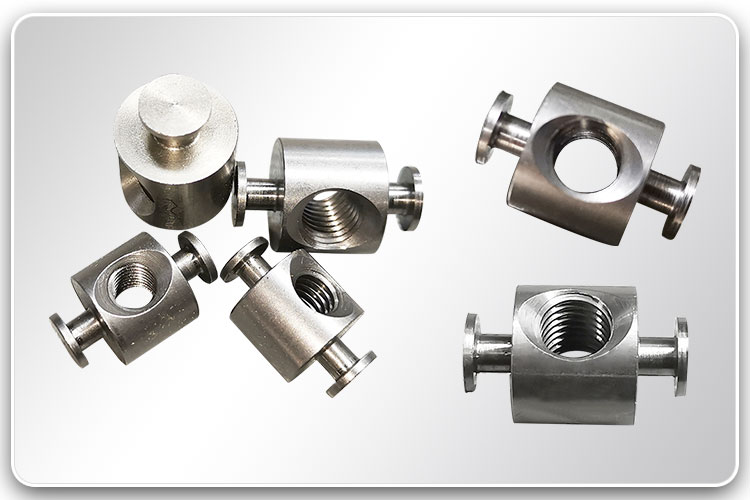

- CNC Machining

- Plastic Injection Molding

- Clamping Ring Parts

- ODM/Patented Products

- Shingle Remover

- Red Ripper

- Ladder Mount

- Kayak Anchor

- Canoe Anchor

- Roof Anchor

- Fixed Roof Bracket

- Adjustable Roof Bracket

- Roof Harness Dock

- Roof Bracket Dock

- Roof Adjusta Dock

- Roof Harness Mount

- Roof Endura Bracket

- Send Inquiry

- Download

- News

- Contact Us