Description

Deep drawing is a sheet metal forming process used industrially to produce

cup-shaped, box-shaped, and other complex-curved hollow-shaped sheet parts. The

process creates deep, seamless and round shapes from sheet metal. During deep

drawing, a sheet metal blank is radially drawn into a forming die by the

mechanical action of a punch. It is thus a shape transformation process with

material retention. The process is considered "deep" drawing when the

depth of the drawn part exceeds its diameter.

There are 4 steps for deep drawing process:

-Cutting Blanks

The deep drawing process

starts from a flat disc that blanked from a steel sheet. Auwell improves

material utilization by staggering our blanks to reduce scrap and material

costs. The deep drawing process minimizes waste, optimizing the efficiency of

material usage.

-Starting Cup

After cutting the blank

at the first die station, the blank is cupped around the nose of a punch and

pressed into a die to form a cup. This first deep drawing forming operation increases

the strength of the part through work hardening.

-Keep Drawing

Depending on your desired

length-to-diameter ratio, Auwell will design dies with several draws to create

the basic shape of your deep drawing parts. The forces produced in the deep drawing

process naturally cause the shell wall to thin out, while the shell flange

thickens at each stage. Our professional team designs the die to stretch the

metal as evenly as possible into the part’s desired shape.

-Post-Drawing Process

After obtaining the

desired shape of the product, the following process can be assembled to other

components or as semi-finished products for future processes including

deburring and surface treatment including polishing, zinc-plating, nickel

plating, chormating, powder coating, painting, etc.

The Benefits of Deep Drawing process

-Speed

It’s usually the most

efficient method for orders of large quantities

-Eliminates assembly

steps.

Deep drawing produces

shapes with closed ends. This avoids the need to cut and weld multiple

pieces.

-Seamless

A deep drawing can or

tube shape has no joins. This makes deep drawing an ideal process for anything

that needs to be water or air-tight.

-High accuracy

Parts coming off a

forming press are extremely repeatable. If the die was made correctly, they’ll

also conform very closely to the drawing.

-Produces complex

geometries.

Deep drawing can produce

complex parts like an oil pan for an engine or complex filter housings.

-Produces very strong

parts

Many metals work-harden

as they deform. Essentially, their crystal structure allows a certain amount of

movement but beyond that, it becomes locked. Deep drawing subjects metal to a

lot of deformation, resulting in tough finished parts with high strength.

Auwell is capable of designing and developing necessary tooling for deep

drawing production. CMM is available for sample dimensional inspection. Surface

treatment includes KTL, powder coating, painting, zinc plating. PPAP documents

are available upon request.

Technical Specifications

-Materials

Mild steel, stainless

steel, copper, brass, aluminum, and alloy steel.

-Machine capacity

1,200-ton hydraulic press

machine, 800-ton stamping machine.

Thickness ranged from

0.2mm to 6mm.

Advantages

Our deep drawing

parts offer numerous advantages over traditionally machined, cast, or molded

parts. We can reverse-engineer existing components, and can often combine

multiple parts into a single stamped piece. The advantages of deep drawing

process are:

-Reduce costs

-Reduce waste

-Lower assembly cost and

time

-Improve metal structure

to produce stronger finished parts.

Besides the

technical advantages of deep drawing process, the competitive advantages of

working with Auwell are:

-Rich Experience

More than 20 years of

experience in deep drawing products development and production, especially to

the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 2 weeks

for simple projects.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for deep drawing projects starting from designing,

through prototyping, tooling/fixture development, sampling, mass production,

and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. Other reports include dimensional reports, surface

treatment thickness, and salt fog test reports, etc. We structure our

processes, creating Flow Charts and Control Plans before production, making

sure all QC processes are in accordance with ISO9001-2015 requirements and

drawing specifications.

-Flexible Payment Term

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Applications

Sheet metal fabrication products have widely been used in almost all

industrial sectors including:

-Aerospace and defense

-Automotive

-Energy

-Electronics

-Construction

-Transportation

-Industrial

-Consumer Products

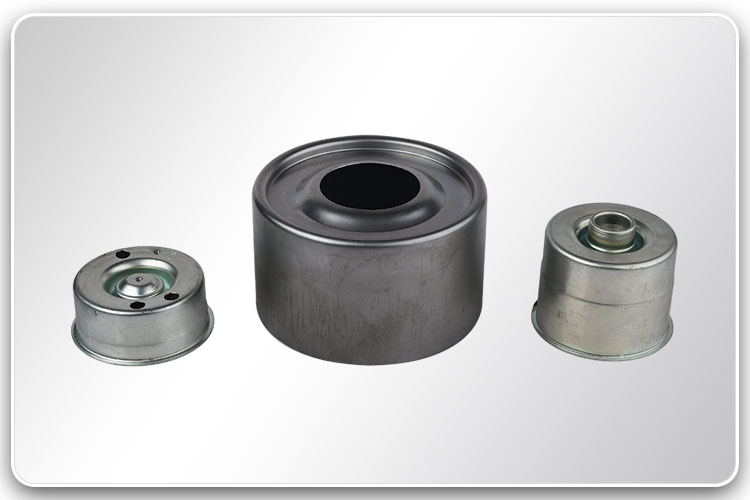

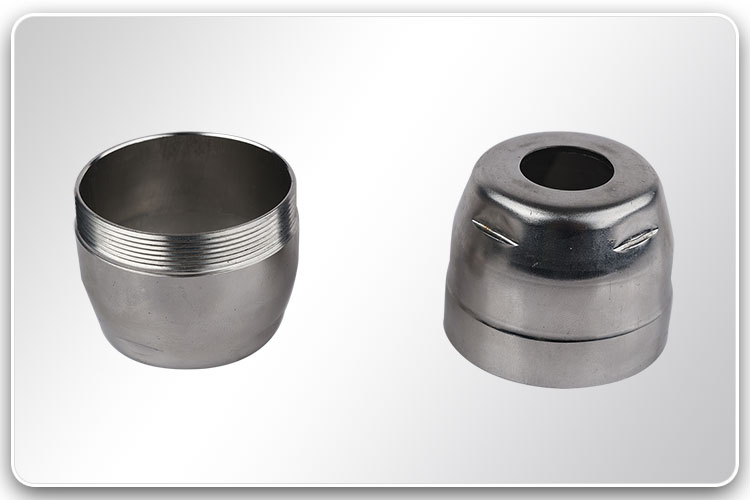

The

following catalogues of deep drawing products are the ones which Auwell has

produced and supplied to our distinguished worldwide clients. Click following

pictures for details. Please be advised, most of the products are for demonstration

purpose only.

Deep Drawing & Spinning

Deep Drawing & Spinning

Elevator Door Pulley

Elevator Door Pulley

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик