High pressure zinc die casting parts is one of the important product lines

that Auwell co-operated with our manufactures for our worldwide clients. Auwell

manufacture is professional in high pressure zinc die casting parts tooling

development, die-casting, CNC machining, surface treatment and assembling, all

processes are carried out under one roof for high productivity and effective

quality control.

Technical Specifications

-Core Element Material

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bolster Material: P20,

1.2312, 1.2738

-Standard Components

HASCO, LKM standard or

custom made

-Popular Product Material

Zamak 3, Zamak 5, ZA8

etc.

-Product surface finishing

Auwell high pressure zinc

die casting parts surface treatment includes but is not limited to: brush, line

polishing, high gross polishing, mirror polishing, sand blaster, anodizing,

zinc-plating, chrome-plating, nickel-plating, powder coating, silver coating,

E-coat, wet paint, silk screening and stenciling etc.

-Maximum Machining Closing

Force

4,000 tons, part weight:

5-30,000g

Advantages

-Rich Experience

More than 20 years of

experience in high pressure zinc die casting parts development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide initial samples in just 5 weeks

for simple projects.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for high pressure zinc die casting parts starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection to high pressure zinc die casting parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request.

Other reports include dimensional reports, surface treatment thickness, and

salt fog test reports, etc. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

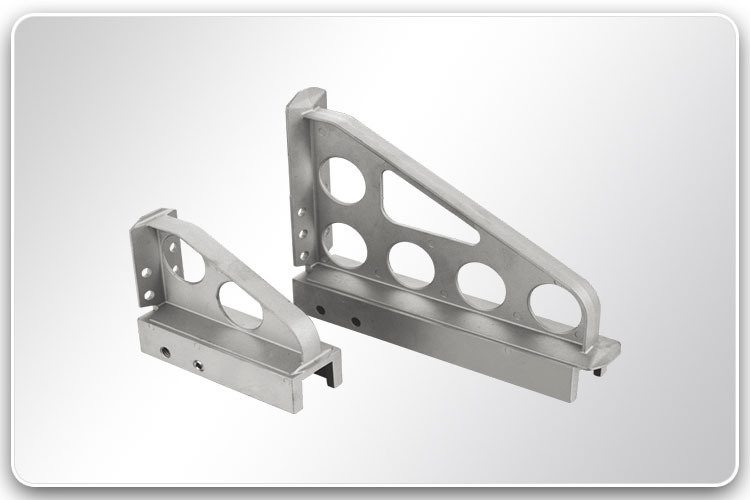

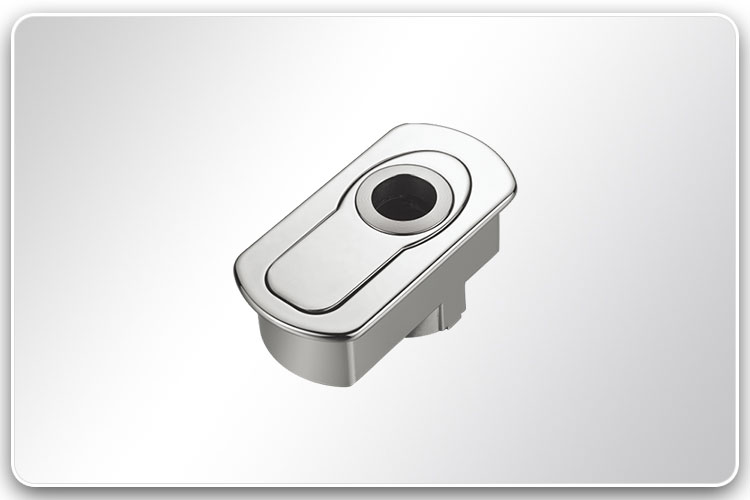

The following

catalogues of high pressure zinc die casting parts are the ones which Auwell

has produced and supplied to our distinguished worldwide clients. Please click

the relevant pictures for details. Please be advised, most of the products are

for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик