Description

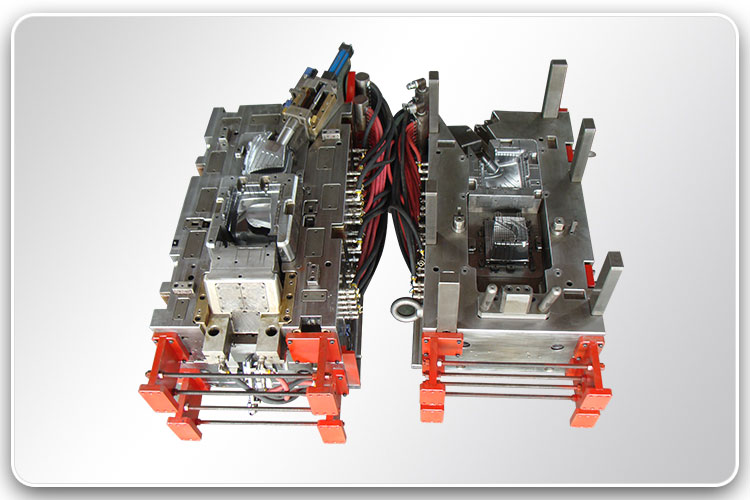

Plastic Injection Mold for Automotive Parts is a typical “Tooling Only

Model” for Auwell’s plastic injection molding services.

The main features for Plastic Injection Mold for Automotive Parts requires

the mold to have long life time, which means, the durability and the

reliability is fundamental for the sustainable and ontime products delivery for

automotive industry.

For Plastic Injection Mold for Automotive Parts, in most of cases, the

mold design is provided by the clients, Auwell produces the tooling with right

material, right heat treatment and right standard components. In some cases, Auwell

offers the tooling design based on the product design and machine data for

client confirmation before production, the details include tooling structure,

lifetime, tooling material, hardness, etc. For designing of Plastic Injection

Mold for Automotive Parts, the most common with globally recognized standard

parts like HASCO, LKM will be selected for easy maintenance and replacement

reasons.

Ningbo enjoys prestigious reputation in Plastic Injection Mold for

Automotive Parts manufacturing. You may find almost all of the automotive

brands purchase plastic injection molds from Ningbo. Our reliable and high

efficiency partners are able to provide quality molds at affordable prices with

fast delivery

Technical Specifications

-Moldbase

LKM, HASCO, 1.2311, P20 etc. 718

-Active Elements

Ø1.2738, 1.2343, 1.2344, H11, H13 etc.

ØASSAB: 718, 718S, 718H, S316/S316H/S316 SUP/S316H SUP, POLMAX/168

ØSAARSTAHL: GS738, GS2311, GS2312, GS638, GS688, GS2316

ØDAIDO: NAK80, NAK55, PX88, PX4, PX5, S-Star(A)

ØBOHLER: M201, M202, M238, M300 ESR, M310 ESR, M310H ESR

-Hotrunner

YUDO, INCOE

-Mould Surface

Photo etching, erode

structure, shot blaster, line polishing, high gross polishing, mirror

Polishing.

-Machines: 100-3,000 ton

closing force

Advantages

-Rich Experience

More than 20 years of

experience in Plastic Injection Mold for Automotive Parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to deliver first sample in 6 weeks.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for Plastic Injection Mold for Automotive Parts starting

from designing, through prototyping, tooling/fixture development, sampling,

mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection or Plastic Injection Mold for Automotive Parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Flexible Payment Term

For tooling, the general

payment term is 50%-40%-10%, meant 50% deposit, 40% after first sample free and

10% 2 weeks after client receive tooling or first batch product delivery

Related Products

Plastic Injection Parts

Plastic Injection Parts

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic Thermoforming Parts

Plastic Thermoforming Parts

Rubber & Silicone Molding

Rubber & Silicone Molding

The following catalogues of Plastic Injection Mold for Automotive Parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик