Auwell started Roofing Tools development in year 2008 under request our North American client. So far, we have developed shingle shovel, ladder dock, roof bracket and roof anchor etc. more than 20 different items. All of the Roofing Tools we developed have unique features compare to existing one on market.

Auwell has a strong R&D team to work with our clients for Roofing Tools development. Our knowledgeable and experienced roofing tools distributors give us sketch or simply ideas specifying the roofing tools they want, our engineers make the concept drawings for confirmation, then move to engineering design for meeting functional requirements, including OSHA guidelines if the roofing tools is safety related. Prototype will be made after drawing confirmation for conducting series of lab test, also onsite trial for product performance and market potential evaluation.

Auwell offers rapid 3D printing prototyping service, it is our absolute competitive advantages to provide our clients valuable suggestions to optimize the design for the roofing tools to be produced with best performance. Right manufacturing process is fundamental for ensuring the roofing tools to be made in super quality at cost effective way. So far, for roofing tools, we have combined forging, investment casting, stamping, machining, plastic injection, welding, powder coating, zinc plating, galvanization process for meeting diverse manufacturing requirements.

Auwell has rich resources of manufacturing partner. By using optimized technology and programming, our roofing tools products have been proven as excellent in quality at an affordable price.

The roofing tools product development process as following:

-Clients’ specification

-Feasibility study

-Concept drawing for approval

-Engineer drawing for approval

-Patent application (if applicable)

-Pricing and confirmation

-Prototyping

-Lab test and onsite test

-Market evaluation

-Tooling and sampling

-Mass production

-Logistic and distribution

-Post sale service including product improvement

For existing roofing tools products, we are able to offer the products with clients’ brand name, trade mark and color scheme (except the tools with patent protection). Distributors that are interested in new roofing tools development, you are welcome to contact us for details.

Advantages

-Rich Experience

More than 10 years of

experience in Ladder Dock production, especially to the North American markets,

with solid understanding of the end users’ expectation in function and quality.

-Fast Turnaround

For existing clients with

confirmed brand, trade mark and package, 45 days lead time after getting order.

For custom branded products, 60 days of delivery time.

-Comprehensive Solution Provider

Auwell provides

comprehensive services for roofing products design and development starting

from designing, through prototyping, tooling/fixture development, sampling,

mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Auwell offers flexible and favorable payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Related Products

Roof Anchor

Roof Anchor

Fixed Roof Bracket

Fixed Roof Bracket

Adjustable Roof Bracket

Adjustable Roof Bracket

Shingle Shovel

Shingle Shovel

Little Shingle Remover

Little Shingle Remover

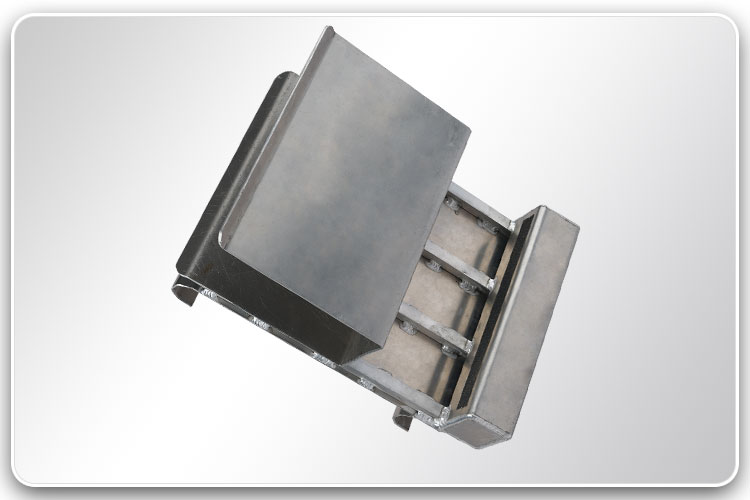

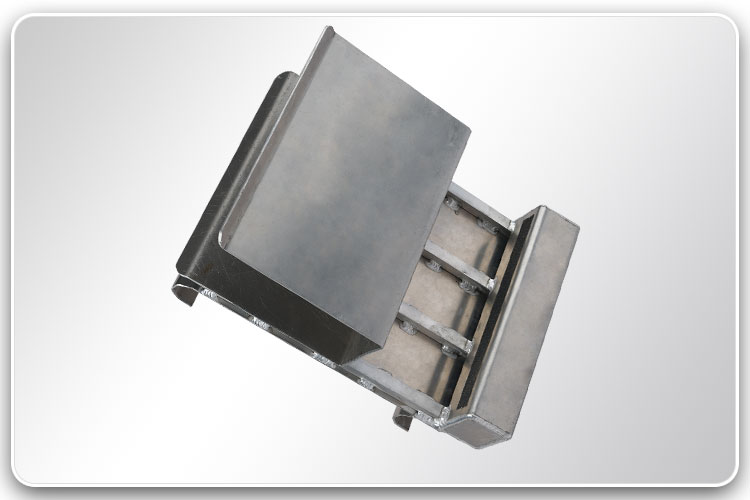

Ladder Dock

Ladder Dock

BundleBuddy

BundleBuddy

Hot Tags: Roofing Tools, Manufacturers, Suppliers, Factory, Customized, Made in China, China

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик